Personal Protective Equipment (PPE): Your Complete Jobsite Guide

August 30, 2018, 7:04 PM /

Safety is a top concern in the construction industry, and for good reason—jobsites can be hazardous. In 2016, trades-related jobs reported the greatest number of lost-time claims in Canada (over 70,000), and Canada’s construction industry also saw the largest number of per-sector fatalities (202) in that year.

There are a variety of steps that can be taken to maximize on-site safety including adjusting processes, isolating dangerous tasks, and providing clear signage. Given the dynamic nature of construction sites, however, the right personal protective equipment (PPE) remains one of the most important tools workers have in their safety tool belt.

We start this article by exploring what PPE is and then go into detail about the types available. Next, we touch briefly on the various national, provincial, and territorial regulations governing how and when PPE should be used before finishing with a look at what you need to know when it comes to replacing PPE.

|

|

|

|

What Is Personal Protective Equipment (PPE)?

PPE is clothing or equipment workers wear or use to ward off on-the-job dangers, either preventing injuries or illnesses outright or reducing the severity if they happen. Common types of PPE include spectacles and goggles, face shields, hard hats, earplugs or earmuffs, respirators, gloves, safety vests, boots, and harnesses.

When Does PPE Need to Be Used?

PPE needs to be used in accordance with both workplace guidelines and government regulations.

More generally, however, it’s important to emphasize that PPE should always be regarded and used as a final measure. According to the hierarchy of controls, preventative steps should first seek to eliminate hazards at the source, reduce them along the path, and finally safeguard the worker through the use of PPE and other protocols.

Who Is Responsible for Providing PPE?

According to Canada’s Occupational Health and Safety Regulations, employers are obligated to:

- Provide the necessary PPE to their employees.

- Ensure it is being worn and used properly at all times.

- Keep it adequately maintained.

That being said, it’s not uncommon for workers to purchase their own PPE (especially things that are more widely available like hard hats, boots, and hearing protection). In these situations, the employer is still responsible for making sure PPE is being used consistently and correctly.

Types of PPE

|

|

|

|

|

|

|

|

|

|

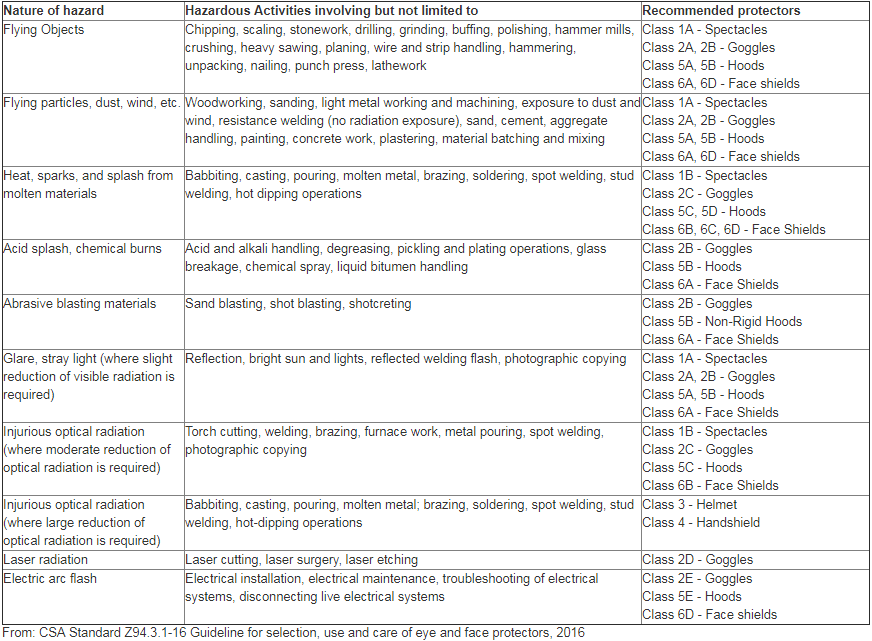

Eye Protection

One out of every two construction workers in Ontario alone might suffer a serious eye injury over the course of their career, which makes eye protection a must-have on the jobsite. Hazards commonly present include flying or falling objects, heat, acid splash, dust, radiation, glare, and abrasives.

In Canada, eye protection is often organized into six categories or classes in line with CSA standards (CSA Z94.3-15):

- Class 1 Spectacles must incorporate some type of side protection, whether permanently attached or removable. Class 1A spectacles feature side safeguards only, whereas Class 1B spectacles feature both side and radiation protection mechanisms.

- Class 2 Goggles are frequently available in two styles, eyecup goggles (engineered to completely cover a wearer’s eye socket and ensure all-around defence) and cover goggles intended to work on top of spectacles. All goggles feature some degree of ventilation to minimize fogging. Class 2A direct ventilated goggles prevent large particles but not liquid or dust, while Class 2B indirect ventilated goggles inhibit large particles, liquids, and dust. Class 2C indirect ventilated goggles take it a step further, delivering protection against radiation.

- Class 3 Welding Helmets are engineered to defend against impacts and radiation. The two kinds most frequently available are stationary plate helmets or lift-front/flipup plate helmets. Stationary plate helmets feature a single filter lens plate, making them ideal for wearers of spectacles, and sometimes can be made to incorporate air purifiers or sound arrestors. Lift-front/flipup plate helmets use three filter lens plats: one in the flip-up cover, an outer lens for cleanliness, and an impact-resistant lens mounted in the helmet itself. When choosing a welding helmet, pay attention to the filter’s shade number and match it to the activity you perform—whether you need enhanced protection against powerful UV rays, improved visibility, or the ability to make more accurate temperature judgments based on colour.

- Class 4 Welding Hand Shields are similar to welding helmets; however front-lift types are not available. It’s worth noting that because users of welding helmets and welding hand shields tend to lift and lower their helmets frequently, they will usually be required to wear Class 1 Spectacles underneath.

- Class 5 Hoods can be engineered to keep you protected against impacts (Class 5A), dust, splashes, and abrasions (Class 5B), radiation (Class 5C), and heat (Class 5D). Hoods are typically non-rigid in their design, which makes them easy to carry and store and ideal for use in tight spaces.

- Class 6 Face Shields are worn to protect against impacts and splashing (Class 6A), radiation (Class 6B), and high-heat (Class 6C).

There are two things to be kept in mind with face shields. First, like with Welding Helmets and Welding Hand Shields, Class 1 Spectacles often should or need to be worn underneath. Second, face shields currently do not meet CSA standards for protecting against UV radiation and total heat together and therefore should not be used in situations where hazards from infrared or UV radiation are present.

Another type of eye protection you might encounter depending on the regulations in your province or territory is respiratory facepieces. Usually, however, this type of PPE is covered in another category (respiratory protection).

Source: https://www.ccohs.ca/oshanswers/prevention/ppe/glasses.html

Head Protection

Hard hats are perhaps one of the most common forms of headwear PPE on a jobsite. According to the CSA Standard Z94.1-15 (Industrial Protective Headwear – Performance, Selection, Care, and Use), the two most common types are:

- Type 1, which protects against impact and penetration at the top.

- Type 2 provides defence at the crown (the top) and on the sides and back.

In addition to the type, there are also three classes of head protection:

- Class 1 is ideal for electrical trades, being made with a non-conductive material and boasting a 20,000V electrical rating.

- Class 2 has an electrical rating of 2,200V and is preferred for more general trades.

- Class 3 headwear has no electrical rating.

Across Canada, CSA or ANSI labels on hard hats will identify the type and class as well as the manufacturer, model, year and month of manufacture, and size. The three basic styles of hard hat are:

- Standard design with a front brim, attachments, and rain gutter.

- Standard design with attachment points but no rain gutter.

- Full-brim design with attachment point.

Remember that hard hats should almost always be worn facing forward. The only exceptions to this rule are if the hard hat has a reverse orientation mark or if the job necessitates wearing it backwards.

Click here to learn more about selecting and caring for PPE headwear from the CCOHS.

Hearing Protection

Noise-induced hearing loss is rapidly becoming one of the most common occupational diseases among construction workers in Ontario. The reason for this is that unlike other injuries, hearing loss tends to happen more gradually. In many cases, workers don’t realize their hearing has been affected until it’s too late.

According to the CCOHS, hearing protection should be worn in situations where noise levels exceed 85 decibels. You can test noise levels using a sound level meter (SLM), a device capable of detecting both intensities and frequencies and weighting them the same way the human ear naturally would.

The two most common types of hearing protectors available are earplugs and earmuffs:

| Earplugs attenuate noise by plugging the ear canal. | Earmuffs provide an acoustical seal. |

|---|---|

| Pros: • Simple to carry and take between sites. • Can easily be used with other PPE. • Comfortable for extended wear in hot, humid conditions and convenient in tight spaces. | Pros: • Designed to quickly fit a variety of head sizes. • If a worker is dealing with a minor ear infection, they can still wear earmuffs. • Easy to see from a distance. |

| Cons: • Easily misplaced due to their small size. • Requires time to properly fit, and they must be adequately and hygienically looked after. • They may be irritating for some workers. • Harder for supervisors to see and therefore monitor compliance. | Cons: • Heavier and less portable. • Uncomfortable and inconvenient in hot or cramped environments. • Cannot be worn as readily with other PPE including eye protection. |

Hearing protection needs to be worn at all times when the situation calls for it. Taking earplugs out or earmuffs off for as little as 3-4 minutes can reduce their effectiveness by up to 95%.

When selecting hearing protection in Canada, always refer to CSA Standard Z94.2 (Hearing Protection Devices – Performance, Selection, Care and Use). You also need to consider noise exposure levels, appearance, the work environment, and overprotection as well as personal preferences among users.

Click here to learn more about selecting and caring for hearing protection from the CCOHS.

Respiratory Protection

Respiratory hazards are present on jobsites of all types and sizes and include:

- Gases like carbon monoxide and hydrogen sulphide.

- Vapours produced by solvents including mineral spirits, toluene, and xylene that are found in products like degreasers and paints.

- Fumes generated by activities like welding.

- Mists that come from spraying materials in the air.

- Dusts generated by crushing, grinding, and sanding materials like insulation (fibrous dusts such as asbestos or glass fibre) or concrete (non-fibrous silica dust).

- Bioaerosols that contain microbes like mold or bacteria and can cause infectious diseases.

In general, there are two types of respiratory PPE available—air-purifying respirators and supplied-air respirators.

| Air-Purifying Respirators | Supplied-Air Respirators |

|---|---|

| Air-purifying respirators purify air as it’s drawn through them. They are always tight-fitting and can be either powered or non-powered: • Powered air-purifying respirators are made with blowers that the wearer needs to carry in order supply themselves with purified air. • Non-powered air purifying respirators rely on the wearer inhaling and exhaling. Typically, air-purifying respirators should not be used in situations where there is an insufficient amount of oxygen (less than 19.5%) or where the concentrations of contaminant are incredibly high. The three types of filter you will find in an air-purifying respirator are particulate filters, gas/vapour cartridges, and combination filters: • Particulate filters remove solid particles (dusts, mists, and fumes) but cannot provide protection against vapours or gases. There are three different classes of particulate filters as well—N (not resistant to oil), R (resistant to oil), and P (oil-proof). • Gas/vapour cartridges use substances to absorb or neutralize gases and vapours. Common sub-types include organic vapour cartridges, acid gas cartridges, and ammonia cartridges. • Combination filters are used when there is more than one type of hazard present or where more might develop. | Supplied-air respirators deliver clean air from an uncontaminated source, which is required to meet CSA Standard Z180.1 (Compressed Breathing Air and Systems). Supplied-air respirators can be either tight-fitting or loose-fitting. The three most basic types are air-line units, self-contained breathing apparatuses, and multi-functional units: • With an air-line unit, the air is supplied by a hose attached to the user’s belt. This means that if there’s an emergency, it can be disconnected rapidly. • Self-contained breathing apparatuses use a cylinder that the wearer needs to carry, which can make them heavy and bulky. • Multifunctional units are ideal for working in confined spaces. |

There are a variety of styles available including mouth-bit respirators, hoods, and helmets as well as quarter, half, and full masks. In selecting the right respirator for the job at hand, you need to consider on-site conditions (the nature of the contaminants, length of exposure, etc.), relevant legislation, and worker-specific attributes like facial hair or deep scars that might interfere with the quality of the seal. Professionals like occupational hygienists can also work with you to decide which type of respirator will be best.

To read more from the CCOHS, click here for information on respirator selection or here for respirator care.

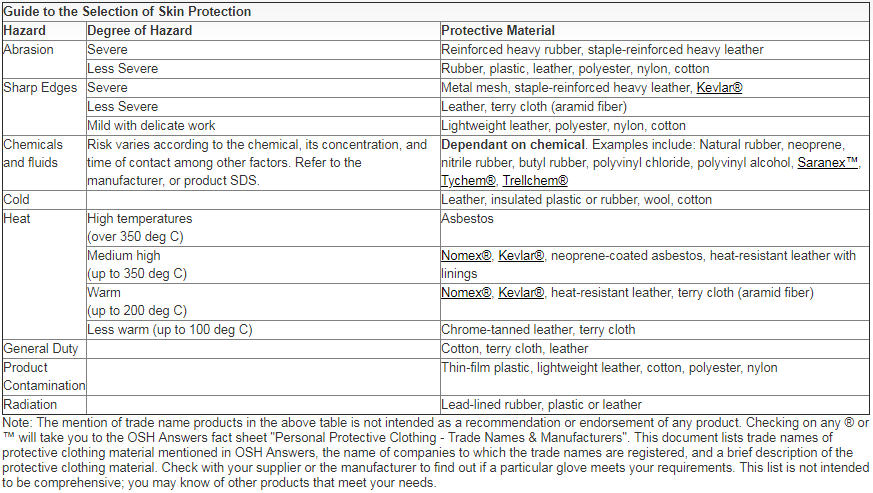

Hand Protection

A study conducted by the Occupational Health and Safety Administration (OSHA) of manufacturing workers revealed some interesting details about hand protection. Among those who suffered a hand injury, 70% of people were not wearing any gloves at all while the remaining 30% had inadequate, improperly used, or damaged PPE.

Hand protection includes items like gloves, mitts, thimbles, cots, finger guards, and barrier creams. Gloves especially come in a variety of materials including leather, cotton, rubber (natural or synthetic), polyester, Kevlar®, nylon, and more.

Some of the most important glove-specific standards used by construction workers across North America come from the American National Standards Institution (ANSI):

| Cut Resistance | Puncture Resistance | Abrasion Resistance |

|---|---|---|

| Level 1: 200-499 Grams to Cut Level 2: 500-999 Grams to Cut Level 3: 1,000-1,499 Grams to Cut Level 4: 1,500-2,199 Grams to Cut Level 5: 2,200-2,999 Grams to Cut Level 6: 3,000-3,999 Grams to Cut Level 7: 4,000-4,999 Grams to Cut Level 8: 5,000-5,999 Grams to Cut Level 9: 6,000+ Grams to Cut | Level 1: ≥10N with a blunt probe or ≥2N with a hypodermic needle Level 2: ≥20N (blunt) or ≥4N (hypodermic needle) Level 3: ≥60N (blunt) or ≥6N (hypodermic needle) Level 4: ≥100N (blunt) or ≥8N (hypodermic needle) Level 5: ≥150N (blunt) or ≥10N (hypodermic needle) | Level 1: ≥100 cycles (tested at 500-gram load) to fail Level 2: ≥500 cycles (tested at 500-gram load) to fail Level 3: ≥1,000 cycles (tested at 500-gram load) to fail Level 4: ≥3,000 cycles (tested at 1,000-gram load) to fail Level 5: ≥10,000 cycles (tested at 1,000-gram load) to fail Level 6: ≥20,000 cycles (tested at 1,000-gram load) to fail |

Other relevant standards to keep an eye out for cover things like chemical permeation, chemical degradation, protection from heat and flames, heat degradation resistance, conductive heat resistance, vibration reduction, and dexterity.

Source: https://www.ccohs.ca/oshanswers/prevention/ppe/gloves.html

Click here to learn more about Superior Glove’s Definitive Guide to Hand Protection.

High-Visibility Clothing

High-visibility clothing is often required for workers who may be endangered by vehicular traffic. CSA standard Z96-15 (High-Visibility Safety Apparel) specifies:

- How high-visibility clothing should reflect light.

- The colours acceptable for use.

- The amount and type a worker needs to wear.

Ultimately, the two key features you need to pay particular attention to when choosing high-visibility clothing are the background material and the retroreflective stripes or bands:

- Background Material: The most common colours seen among construction workers in Canada are fluorescent blaze (safety orange) and international orange. CSA standards do allow some other colours, however you should check your local regulations to ensure you are in compliance.

- Retroreflective Stripes/Bands: These also help to make workers more visible, especially in conditions with lower levels of light. In many jurisdictions, rules will outline that the stripes must be both retroreflective and fluorescent, and they must be present on the front and the back of the clothing. Additionally, you may find standards relating to stripe thickness and guidelines for overnight use.

| Why Orange? Orange is a complementary colour to blue, which means it provides the greatest degree of contrast against the colour of the sky and other background colours likely to be present on the jobsite. |

Limb and Body Protection

PPE in this category includes:

- Flame and chemical-resistant clothing

- Leather aprons and leggings

- Full body suits

- Leg, arm, chin, and belly guards.

These types of equipment are meant to keep workers protected from job exposure hazards like extreme temperatures, fire and flames, impact, corrosives, abrasives, and more.

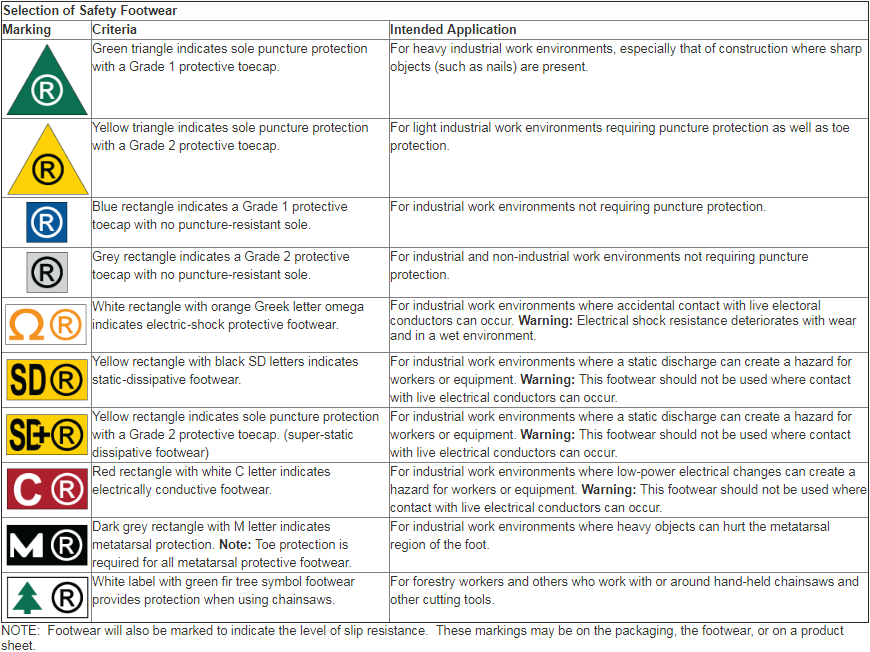

Foot Protection

Safety footwear is required to mitigate risks presented by conditions like uneven terrain, slippery surfaces, and exposure to extreme heat or cold as well as liquids, abrasives, sharp objects, and corrosives. Protective shoes and boots typically incorporate features like a box toe to defend against impacts and a puncture-resistant sole or insole.

The CSA identifies three grades of protective footwear:

- Grade 1 offers the highest degree of protection and is recommended for industrial jobsites (especially construction) where sharp objects like nails are present.

- Grade 2 is suited for light industrial work.

- Grade 3 foot protection is best for work environments that do not require puncture protection.

In most circumstances, Grade 1 work boots or shoes are mandatory on construction sites across Canada. Though not required, high or medium-cut footwear is often recommended to stabilize the ankle and provide increased protection against impacts and abrasions.

Source: https://www.ccohs.ca/oshanswers/prevention/ppe/footwear.html

Fall Protection

Falls are the number one source of critical injuries and deaths among workers on construction sites in Ontario. Often, accidents happen because equipment has been used incorrectly or not at all.

In addition to the effects of an impact, some of the other dangers associated with a fall include:

- Bottoming out, which happens when a worker hits the ground before a fall arrest stops them.

- The pendulum effect or swing fall when a person sways from side to side, possibly coming into contact with other objects or surfaces.

- Suspension trauma, which is possible if someone stays suspended too long.

There are a few different categories of fall protection including:

- A guard railing, an adaptable and reliable way to protect workers. It can be made of wood (often specific types), wire rope, or metal.

- A fall arrest system that prevents workers from hitting the ground or objects below. Typically, fall arrest systems need to include an anchor point capable of withstanding either the maximum load imposed on it or a weight of approximately 1800kg (whichever is greater), a lanyard attached to a worker’s harness, the full-body harness itself, and a rope grab. Depending on the total fall distance, additional measures like personal energy absorbers may also be needed.

- A travel restraint system that allows workers to reach the edge of a surface without falling over. CSA-approved equipment again includes components like sufficient anchorage, full-body harnesses, lanyards, and lifelines.

- Safety nets are used in situations where guard rails or fall arrests (anchorage and lifelines) can’t be set up like during bridge work.

To minimize fall-related hazards, many jurisdictions outline rules surrounding the training and equipment required for individuals working at height. You need to understand what standards and regulations apply to you when developing fall prevention protocols and practices and also stay up to date with CSA standards (including CSA Z259.1-05, Z259.2.2-98, Z259.2.5-12, Z259.9.2.3-99, Z259.10-06, Z259.11-05, Z259.12-01, and Z259.14-01), as they are updated regularly.

How do you choose and use the right ladder for the job at hand? Read our blog to find out!

National and Provincial Regulations Surrounding the Use of PPE on the Jobsite

In Canada, we have fourteen jurisdictions—one federal, three territorial, and ten provincial—that each have their own specific occupational health and safety legislation covering topics including PPE. Many basic principles are the same, but details can vary.

Nationally, the Canadian Centre for Occupational Health and Safety produces legislation and standards to promote health and safety in the workplace. Click here to learn more.

To find out more about regulations in each province, there are a range of professional associations you can consult and reach out to for further guidance:

- Northern Safety Network Yukon

- Northern Construction Safety Association

- BC Construction Safety Alliance

- Alberta Construction Safety Association

- Heavy Construction Association of Saskatchewan

- Manitoba Heavy Construction Association

- Infrastructure Health and Safety Association

- ASP Construction

- New Brunswick Construction Safety Association

- Construction Safety Nova Scotia

- Newfoundland and Labrador Construction Safety Association

All of the organizations above are part of a larger umbrella organization, the Canadian Federation of Construction Safety Associations (CFCSA).

Knowing When It’s Time to Replace PPE

As you might expect, this changes depending on factors like the type of PPE it is and how it’s used.

To determine whether or not it’s time to replace your PPE, you need to ask yourself three questions:

1. What do my manufacturer guidelines say?

Manufacturers will provide necessary information about how long you can expect their PPE products to last. Some may also identify signs to watch for that will indicate whether or not a product has reached the end of its service life, however this is not always the case.

2. Has the PPE sustained damage?

Even if a piece of PPE hasn’t yet reached the end of its manufacturer-designated service life, if it is damaged (whether while in use or during transport or storage), it must be removed from service and either repaired or replaced.

3. Has the PPE failed an inspection?

Think of the inspection as your last line of defence. Regardless of how old the PPE is or whether or not it has been damaged (to your knowledge), if it doesn’t pass a routine inspection it needs to be retired. In some cases you might be able to carry out repairs, though other times you will simply need to replace it.

Alongside engineering and administrative measures that control hazards along the path, ensuring your PPE is in good working condition and is suited to the job at hand is the best way to keep workers protected and defend against workplace injuries and fatalities.

Fastening House specializes in providing safety and PPE products from industry-leading manufacturers like Degil, Superior Glove, and Dynamic Safety International. Shop our selection online and get free nationwide shipping on orders over $150!

Read more from Fastening House:

- 5 Actions You Can Take to Maximize On-Site Safety

- Choosing the Right Diamond Blade for Your Saw

- 5 Reasons Why Effective On-Site Material Management Matters

Icon made by Freepik, Kiranshastry, Smashicons, and Dave Gandy from www.flaticon.com

- Fastening House Acquires Sabre Industrial Supplies Limited - February 22, 2023

- Fastening House Supports Skilled Trades Expansion at Durham College - April 26, 2022

- Fastening House Continues Its Legacy - April 4, 2022