How to Choose and Use the Right Ladder for the Job at Hand

May 31, 2018, 1:46 PM /

Ladders are staple items on jobsites from coast to coast, but not every ladder is created equal. Some are built to be lighter and more mobile, while others are designed to be safe for use near heat or electrical currents. To get the best performance out of them and keep crews protected, you need to make sure you pick the ladder best suited for your needs.

are staple items on jobsites from coast to coast, but not every ladder is created equal. Some are built to be lighter and more mobile, while others are designed to be safe for use near heat or electrical currents. To get the best performance out of them and keep crews protected, you need to make sure you pick the ladder best suited for your needs.

Featherlite created a comprehensive guide that covers how to choose, use, inspect, and maintain a variety of ladder types, styles, and materials. We’ve highlighted some of the key points here for you, though we also encourage you to download the full guide for yourself to learn more.

Selecting the Ideal Ladder

Featherlite recommends focusing on four characteristics—type, size, material, and duty rating.

1. What type of ladder is required?

The three main kinds of ladder that will be available to you are:

- Straight or extension ladders require support at both the top and the bottom, but are incredibly versatile and come in a wide array of sizes.

- Step ladders are built to be self-supporting. They are available in a variety of styles and sizes and are typically meant to be used by one individual at a time.

- Combination ladders are designed for maximum adaptability. They can be configured in a range of positions to suit each task and can be stored compactly when not in use.

Keep in mind that each type of ladder comes with unique safety considerations. Featherlite goes through some of these on pages 14-20 of its guide.

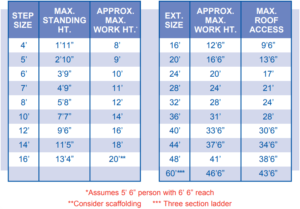

2. What size of ladder do you need?

The size of ladder required will vary depending on the type of ladder you’re using. Featherlite recommends you start by measuring from the ground up to the highest point you need to access. Using that measurement, consult the charts found below and on page eight of Featherlite’s ladder safety guide.

For straight and extension ladders in particular, remeber the 1:4 rule. In essence, this says that your ladder’s feet should be set back one horizontal foot for every four feet of vertical distance between the ground and the upper support.

3. What material should the ladder be constructed from?

The four most common ladder materials are:

- Aluminum, the most popular, is relatively lightweight and resistant to corrosion. Due to its conductive properties, however, it should never be used near heat or sources of live electricity.

- Fiberglass is heavier than aluminum. It’s also impervious to moisture and, unlike aluminum, is a non-conductor of electricity and heat.

- Wood is a non-conductor as long as it’s dry, although it’s heavy and more prone to general wear-and-tear.

- Steel ladders are built to meet specific load requirements. They conduct heat and electricity and are vulnerable to rust.

It’s important to consider how, where, and when your ladder will be used in determining which material will be most suitable for you.

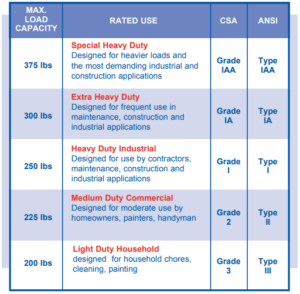

4. What duty rating is needed?

The duty rating is especially important to pay attention to as you never want to exceed the maximum load rating for the ladder you’re using. When doing your calculations, always factor in everything the ladder will need to support including the user, their clothes, as well as any tools and materials they will be using.

Featherlite has engineered and tested its products to meet or exceed all applicable CSA and ANSI specifications. See the below chart for a complete breakdown of Featherlite’s duty ratings.

Using Your Ladder Safely

Featherlite shares a number of ladder safety tips including:

- Avoid using ladders when you are feeling unwell or during poor weather (particularly high winds or thunder storms).

- Do not leave ladders unattended after they are set up.

- Do not use ladders as scaffolding or straddle the rungs. Unless explicitly stated otherwise, the majority of ladders are not intended to be used this way.

- Avoid obstructions and always make sure ladders are properly secured.

- Never place a ladder in front of an unlocked door.

- If something heavy has dropped on your ladder, promptly remove it from use until you can properly inspect it.

- Besides small identification marks, do not paint ladders. Doing so can hide defects and could impair flashover-voltage properties for wood or fibreglass ladders.

Though some of these suggestions seem common sense, it’s important to emphasise that ladder safety must be taken seriously at all times. Improper ladder use alone sends over 4,000 Canadians to the hospital every year.

To read more about safety considerations for each type of ladder, see pages 14-20 in Featherlite’s guide.

Inspecting Your Ladder before Each Use

Before you set up and step onto your ladder, take a few minutes to inspect it and look for warning signs like:

- Damaged, twisted, or bent side rails. Remember that once a rail has been bent you shouldn’t attempt to unbend it, since its strength will have already been compromised.

- Loose or cracked rungs, both of which are telltale signals that the ladder needs to be taken out of service until it’s repaired. Do not weld rungs. Unless they are designed that way already, welding will soften the metal and weaken its structural integrity.

Featherlite goes into more detail about inspecting step, extension, and fibreglass ladders on pages 22-25 of its guide.

Maintaining and Repairing Your Ladders

Maintaining and Repairing Your Ladders

Maintenance

Like any piece of equipment on your jobsite, ladders need some periodic preventative maintenance to keep them in good working order:

- Clean the whole ladder regularly.

- Keep all moving parts slightly lubricated.

- Slide guides and safety feet must be replaced if they’re worn.

- The rope assembly should be changed at least once per year.

Fibreglass ladders require some extra TLC. To maintain maximum dialectic properties, they need to be routinely washed with a mild detergent and waxed with an exterior quality paste wax. This helps keep dirty and water out of any scratches or other imperfections.

To learn more about setting up a control and maintenance program on your jobsite, check out page 27 in Featherlite’s guide.

Repair

Not every ladder component can be replaced, but there are some that can:

| Extension Ladder | Step Ladder |

|---|---|

| Safety feet | Spreader arms |

| Rung locks | Safety feet |

| Rope assembly | Head and pail tray |

| Cog wheels | |

| Pail tray | |

| Protective end caps | |

| Slide guides | |

Replacement parts must be correctly installed to maintain the safety of your ladder. Riveting will occasionally be required, however in the majority of cases self-locking washers, bolts, and nuts will suffice.

If you have concerns about the soundness of a ladder, remember the rule—when in doubt, tag it out! Provided a technician is able to properly fix it, you’ll be able to bring it back into service. If the damage is too extensive, however, you’ll need to dispose of it and begin looking for a replacement that will help you get the job done efficiently and safely.

Featherlite is the number one leader in the Canadian industrial ladder market. Since 1949, its name has been synonymous with durability, dependability, and quality. Shop Featherlite ladders online with Fastening House!

Read more from Fastening House:

- Introducing Ironman™ Grinders from Walter: Heavy-Duty Grinders for Heavy-Duty Applications

- 5 Reasons Why Effective On-Site Material Management Matters

- 5 Actions You Can Take to Maximize On-Site Safety

- Fastening House Acquires Sabre Industrial Supplies Limited - February 22, 2023

- Fastening House Supports Skilled Trades Expansion at Durham College - April 26, 2022

- Fastening House Continues Its Legacy - April 4, 2022